A young Graham Wrench at work on the Oramics synthesizer.

A young Graham Wrench at work on the Oramics synthesizer.

In the early '60s, pioneering British composer Daphne Oram set out to create a synthesizer unlike any other. The engineer who turned her ideas into reality was Graham Wrench.

To celebrate the 50th anniversary of the BBC Radiophonic Workshop in April 2008, I wrote about its history for Sound On Sound (you can read the article on‑line at /sos/apr08/articles/radiophonic.htm). I've always felt that Daphne Oram's importance has been underestimated, both as a co‑founder of the Workshop and as an electronic composer, so I tried to redress this by including as much as I could about her graphically controlled Oramic synthesizer. This was not easy, as Daphne died in 2003 and I was unable to find anyone who'd even seen the Oramic System, let alone knew how it worked. I did my best, but shortly after the magazine went on sale, an email was forwarded to me by Sound On Sound.

"I enjoyed the article very much,” said the writer. "With reference to the bizarre design concept of the original Oramics machine, you might be interested in some background as to why and how it took shape! I was the engineer who originally turned Daphne's concept into a reality, with an extremely tight budget and a lot of inverted, lateral thinking.” It was signed: "Yours respectfully, Graham Wrench.”

I had to meet this man! So off I went to rural Suffolk, where Graham lives in a little house crammed with engineering wonders. There are musical instruments, home‑made telescopes, model railways, vintage photographic gear… There's even a steam railway museum just down the road! Despite these temptations, I managed to spend a whole afternoon listening to Graham's account of how Oramics really worked, and how he came to design and build the prototype.

Above The Radar

Graham Wrench was born in 1937. His father was a professional musician, who started as a silent film pianist and later joined the ranks of the London Symphony Orchestra as a double bass player. During the later part of the Second World War he became the LSO's secretary — working from the infant Graham's bedroom after the orchestra's London office was bombed. When the war ended, a new London orchestra called the Philharmonia was formed specifically to record all the classics; Graham's father became their fixer, arranging all the recording sessions and booking musicians. So young Graham had an enviable life — when not in school, he was either sitting in on recording sessions and rehearsals, or hanging out backstage with the musicians of various orchestras. It was probably through the LSO that Graham first met Daphne Oram: the LSO had the Proms in those days, and Daphne was a BBC 'music balancer' responsible for many live broadcasts from the Albert Hall.

"Daphne's job involved more than just setting the levels,” recalls Graham. "She had a stack of records, and the printed scores of whatever pieces the orchestra was due to play. If anything went wrong in the auditorium she was expected to switch over seamlessly from the live orchestra to exactly the right part of the record!”

Because his father knew Daphne, Graham managed to get himself invited to other recording sessions at the BBC. Although still a schoolboy, he came to know many recording engineers, and the prominent conductors and musicians of the day, as he learned all he could about recording and microphone techniques. Encouraged by his father, Graham began to dabble in electronics and built his own radios and amplifiers. Soon their house boasted what must have been one of the world's first home recording studios.

"This would have been in the mid‑'50s,” says Graham. "Dad and I soundproofed the sitting room and we used to record his musician friends when they came round. There was a washing line strung across the room, holding a pair of ribbon mics; I'd acquired a cutting lathe, so I recorded direct to disc. The lathe was meant to run at 78rpm, but I changed the gearing and converted it to 33 and a third so I could cut long‑playing records, in mono.”

At the age of 17, Graham left school to join an electronics research company who were developing the first miniature thin‑film capacitors. Access to high‑quality components meant he could now experiment with sound oscillators, and he even built his own oscilloscope. But when he reached 18 he had to do his compulsory National Service. "I hadn't received my call‑up papers,” Graham recalls: "So I went along anyway, and told them I wanted to work in radar. This wasn't allowed, as the training was too long and the RAF reckoned they wouldn't get any benefit from you in only two years. So I offered to take the exam there and then; I passed, but had to agree to stay on for four years.”

Military radar at that time used cutting‑edge technology that pushed valve circuitry to its limits: soon Graham was learning the latest high‑frequency 'pulse circuitry' techniques. "For ground‑based radar,” he says, "we had something called a 'video mapper' that scanned a photographic image, such as an outline of the local coastline, and allowed it to be superimposed on the radar image. I soon found I could mess about with this and add my own images, or comic messages for the radar operators.” Graham would later adapt this technique for the waveform scanner used in the Oramics system.

Military radar at that time used cutting‑edge technology that pushed valve circuitry to its limits: soon Graham was learning the latest high‑frequency 'pulse circuitry' techniques. "For ground‑based radar,” he says, "we had something called a 'video mapper' that scanned a photographic image, such as an outline of the local coastline, and allowed it to be superimposed on the radar image. I soon found I could mess about with this and add my own images, or comic messages for the radar operators.” Graham would later adapt this technique for the waveform scanner used in the Oramics system.

Oram's Folly

In 1959 he left the RAF and took a job as an engineer with the International Broadcasting Company. IBC had recording studios very near the BBC's Broadcasting House, in central London. They recorded music for TV jingles and some 'Light Classics', but also had a couple of very high-quality disc‑cutting lathes, one of which was used to cut the very first stereo test records for the Decca and Pye labels. One day Graham was alerted to a rumpus going on in one of the IBC studios — a disgruntled client, he was told, was "causing chaos”.

"When they told me it was a lady, I had an idea who it might be,” says Graham. "Sure enough, it was Daphne Oram. She had her own studio in Kent by this time and had brought in some tape loops that she made for a commercial — but she was complaining that our machines were playing them at the wrong speed.” It turned out that Daphne's tapes had likely been stretched by her own Brenell machines, which could have notoriously vicious brakes. She remembered Graham, who was able to smooth things over.

During her brief tenure at the Radiophonic Workshop, Daphne Oram did more than anyone else to establish its experimental ethos.A few years later, in early 1965, Daphne got back in touch to ask Graham if he was interested in working for her on an exciting new project. So he and his wife drove down to Daphne's home and studio at Tower Folly, a converted oast‑house in Fairseat, Kent.

During her brief tenure at the Radiophonic Workshop, Daphne Oram did more than anyone else to establish its experimental ethos.A few years later, in early 1965, Daphne got back in touch to ask Graham if he was interested in working for her on an exciting new project. So he and his wife drove down to Daphne's home and studio at Tower Folly, a converted oast‑house in Fairseat, Kent.

"There was an octagonal room,” remembers Graham, "where she'd set up her studio, but on a board covering a billiard table in an adjoining reception room was displayed the electronics for Oramics. There wasn't very much of it! She had an oscilloscope and an oscillator that were both unusable, and a few other bits and pieces — some old GPO relays, I remember. Daphne didn't seem to be very technical, but she explained that she wanted to build a new system for making electronic music: one that allowed the musician to become much more involved in the production of the sound. She knew about optical recording, as used for film projectors, and she wanted to be able to control her system by drawing directly onto strips of film. Daphne admitted the project had been started some years before, but no progress had been made in the last 12 months. I said I knew how to make it work, so she took me on. I left my job with the Medical Research Council and started as soon as I could.”

Work on the Oramics System had actually begun in 1962, with the help of a grant from the Gulbenkian Foundation. Daphne's brother had developed some of the mechanical side, building the film transport system and a cleverly designed spring clutch that would protect the film in case of jamming. But the project also required sophisticated electronics, and there it had floundered. Daphne wanted a machine that offered complete control over the sounds it made. That meant any waveform, at any frequency — from one cycle per second up to the limit of hearing. Graham went back to basics. Drawing on his RAF radar experience, he began by designing a time‑base for the waveform generator. This was not easy, as he recalls:

"We had so little in the way of components in those days. Transistors had only recently appeared on the general market, so they were still pricey. I needed to use light‑sensitive photo‑transistors but they were far too expensive, at almost a pound each. This was at a time when a good wage was about £25 a week! But I started experimenting and discovered that I could take apart the ordinary transistors. Scraping off their covering of paint turned them into photo‑transistors, so I made my own. I think the whole system eventually had about 30 to 50 transistors in it, which cost quite a lot of money. These days we can get four and a half million transistors just on one CPU chip… Memory too, had to be made by hand back then — by winding a few turns of copper wire around a ferrite ring. That would be just one bit — switchable between nought and one.”

"We had so little in the way of components in those days. Transistors had only recently appeared on the general market, so they were still pricey. I needed to use light‑sensitive photo‑transistors but they were far too expensive, at almost a pound each. This was at a time when a good wage was about £25 a week! But I started experimenting and discovered that I could take apart the ordinary transistors. Scraping off their covering of paint turned them into photo‑transistors, so I made my own. I think the whole system eventually had about 30 to 50 transistors in it, which cost quite a lot of money. These days we can get four and a half million transistors just on one CPU chip… Memory too, had to be made by hand back then — by winding a few turns of copper wire around a ferrite ring. That would be just one bit — switchable between nought and one.”

Inside Oramics

Graham described for me in detail how some elements of the Oramics machine worked. The waveform generator really was an oscilloscope working backwards! Analogue oscilloscopes use a Cathode Ray Tube (CRT), which produces a dot of light on its glass screen by exciting the phosphor coating with a stream of electrons. Inside the tube are two pairs of metal plates, which can be electrically charged to deflect the electron stream and move it around the screen. One pair of plates controls the 'X' axis and another pair the 'Y' axis. With no charge on any of the plates, all that will be seen is a bright dot in the centre of the screen.

Graham Wrench's Oramic waveform generator used a six‑inch CRT mounted inside a lightproof box, with a 5x4‑inch photographic slide carrier fixed to the front of its screen. Mounted some distance in front of the CRT was a photomultiplier tube, arranged so as to detect light from anywhere on the screen. In the slide carrier was placed a transparency with an image of the required waveform; but this was not, as generally believed, simply a line drawing. The shape was filled in with solid black below the line and was left transparent above it, looking rather like the silhouette of a mountain range.

Across the bottom of the CRT screen a dot of light was made to trace a horizontal line by scanning repeatedly from left to right along the 'X' axis. If the beam happened to be obscured by the lower, opaque part of the drawn waveform, no light would be detected by the photomultiplier tube. If so, the beam was told to move higher up the screen until the photomultiplier could see it. In this way the moving dot of light was forced to follow exactly whatever profile was drawn on the transparency. Altering the voltage of the CRT's Y‑axis deflection plates controlled the up and down movement of the dot. The charge on these plates is very high — usually several hundred Volts. But if fluctuations in the Y‑axis voltage were scaled down to within just a Volt or so, it could be connected to an audio amplifier… And that is exactly how the Oramics machine generated its sound: the audio output was tapped off the Y-axis voltage of the CRT.

Whatever shape was placed in front of the screen became just one cycle of a repeating waveform. The speed at which the dot of light travelled across the screen on the 'X' axis was controlled by the time‑base unit, and was adjustable over a very large range so that the speed of the scan dictated the frequency of the sound it produced. If the beam travelled across the screen 440 times every second, it would scan the drawn waveform 440 times, producing a pitch of 440 Hertz, or the 'Concert A' above middle C.

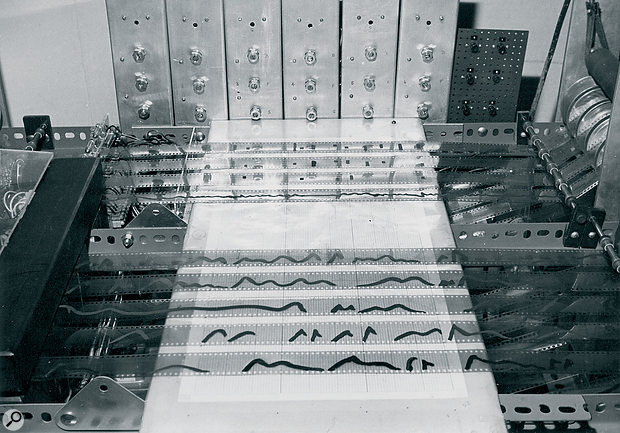

The Oramics machine was programmed by painting spots and lines on 35mm film. In many ways, it was the first digitally controlled synthesizer.The dot of light was required to travel across the screen in one direction only; it then had to jump quickly back to its starting position and repeat. If not fast enough, this 'flyback time' would produce an audible glitch when converted to sound. But Graham had already learned to how to solve this problem in his days as an RAF radar fitter. He was able to design his time‑base so that instead of 'drifting' back to the start, the dot of light was driven back in less than one megacycle, making it inaudible.

The Oramics machine was programmed by painting spots and lines on 35mm film. In many ways, it was the first digitally controlled synthesizer.The dot of light was required to travel across the screen in one direction only; it then had to jump quickly back to its starting position and repeat. If not fast enough, this 'flyback time' would produce an audible glitch when converted to sound. But Graham had already learned to how to solve this problem in his days as an RAF radar fitter. He was able to design his time‑base so that instead of 'drifting' back to the start, the dot of light was driven back in less than one megacycle, making it inaudible.

Daphne insisted on total flexibility for the sound composer, so she chose to work with frequency, rather than pitch, as Graham remembers:

"Daphne told me that she wanted to work outside of the orthodox musical scales: she thought in terms of pure sound, so rather than regarding a note as being an 'A' she preferred to think of it as a frequency of 440 cycles per second (what we'd now call 440 Hertz). So I needed to devise a convenient way of setting the frequency of my time‑base unit. Everything was to be controlled by drawing on 35mm film, and I found I could fit a maximum of four home‑made photo‑cells side by side across one strip of film. I decided to use four separate strips of film for setting the frequency: one strip would set the number of units of cycles per second; one set the number of tens of cycles; a third set the number of hundreds of cycles; the last would set the number of thousands of cycles per second. The actual 'programming' of each was done by painting spots on film — using the binary system!”

Bits & Bases

There has always been some confusion about the use of the word 'digital' in relation to Oramics. I thought (wrongly) that it simply meant that marks on film were used to turn switches on or off — but Graham really did use a digital system, of sorts. To understand it, though, it helps if you can cast your mind back to maths lessons from school days. This is digital taken right back to basics…

The Oramics machine was developed on a very tight budget and required some ingenious lateral thinking on Graham Wrench's part — such as scraping the paint off transistors to make them into light‑sensitive photo-transistors.

The Oramics machine was developed on a very tight budget and required some ingenious lateral thinking on Graham Wrench's part — such as scraping the paint off transistors to make them into light‑sensitive photo-transistors.

"It's simple, but very effective,” he says. "Each of the strips of film is divided, if you like, into four usable 'tracks' across its width — each of which can be set to on or off by putting a spot of paint in the appropriate place on the film, to be read by a photo‑cell. Remember how the binary system works? Well, if each strip of film has four tracks, we can use them as four places of binary digits. The track on the lower edge of the film does nought or one; the next one up does nought and two; the next does nought and four; the top‑most track does nought and two again: hence, weighted binary. So it's very simple to 'program' each strip of film with a number — it only has to be between nought and nine — just by painting up to four spots on the film.

"Imagine that you've put a waveform picture in the scanner. If you'd like that sound to play at a frequency of 440 Hertz, then you go first to the strip of film that programs the hundreds of cycles per second. There are four available film‑strips of four tracks each, so just put a spot on the third track of the third film from the bottom (the hundreds). Then go to the film strip that programs the tens of cycles per second, and do the same. That's it — you've programmed 440 Hertz! When the film is run, those two spots of paint will be read by the photo‑cells, which in turn, control latching relays that switch in banks of resistors and make the time‑base run at whatever frequency. So you see, it is digitally controlled — but not how you'd imagine it! I know it seems a strange way to play a tune, but with a bit of practice it becomes quite intuitive.

"Eventually,” says Graham, "I intended the system to be expanded, so any number of scanners could be added in parallel. They could be tuned differently, and used to add harmonics. Either all of them could be sync'ed up to a single time‑base, or they could be left to free‑run… There was scope for total flexibility, so you'd be able to build up any waveform you wanted.”

Fading Light

Graham had succeeded in controlling pitch and timbre: the next important parameter to tackle was level. It's hard to imagine it now, but continuously variable volume controls did not exist in 1965! The BBC and other professional broadcasters used 'stud faders' — lines of brass contacts, each connected to a resistor, which could be swept with a wiper to change level in a series of steps.

"To get smooth volume changes was tricky — but I also needed a range of over 60dB,” Graham says. "Variable capacitors were used in radios, but they were noisy. So I chose optical instead. It's a method that was used in some of the classic compressors to allow smoother control; a light is faded up and down and that controls the audio level by means of a photo‑resistor. But there were no LEDs then — only thermal filaments. I had to use torch bulbs, so yet more circuitry had to be added to compensate for the bulb ageing…”

Graham's system worked, though, and by drawing on a strip of film, it was possible to create complex envelopes. Just two more parameters were needed: tremolo and vibrato. These could be drawn, but each required its own strip of film. A wobbly line was painted for each: the tremolo track produced variations in level and the vibrato was connected to the time‑base to influence pitch.

Looking at early photographs of the Oramics machine, I noticed that the marks painted onto the strips of film were just squiggly lines; I asked Graham if these needed to be filled in solidly below the line, as the waveform picture in the scanner did. "No — I found a way around that,” he replied. "It would have taken so long to fill in the patterns that it wouldn't be practical. It was possible to set a null point, by tweaking the response and the position of the photocell, so just a painted line was enough. Painting the squiggles was really very intuitive! With, say, vibrato, one could imagine how it should sound — and just paint the lines spontaneously.”

A Bitter End

Graham Wrench today.Graham worked on the Oramics project for about 18 months but never saw it fully working. At the time he left, in 1966, the machine was running six strips of film. This was later expanded, he believes, to 10: extra scanners were added, and more tracks were required to switch them in and out.

Graham Wrench today.Graham worked on the Oramics project for about 18 months but never saw it fully working. At the time he left, in 1966, the machine was running six strips of film. This was later expanded, he believes, to 10: extra scanners were added, and more tracks were required to switch them in and out.

"I've seen pictures of the later version,” says Graham, "and some other engineer has obviously built more clones of my scanner and time‑base, and added them to the system.”

So why did Graham leave before completing the project?

"It was all very strange, and I still don't understand it,” he says. "Daphne was taken suddenly ill — she was found by her housekeeper, collapsed on the floor of her studio. Some BBC friends rushed her off to a private clinic; they thought at first she'd had a brain haemorrhage, but it was never made clear what it really was. She was such an intense person; I personally thought it was exhaustion — some sort of a breakdown. I also worried that it could have been the Oramics machine that had caused it. It could produce subsonic frequencies — down to about 5Hz — and it was all too easy to leave it switched on and not realise. Around that time there used to be a man who gave lectures on sound; his trick to end the show was to play a low sound at the resonant frequency of the human bladder. You can imagine — the room emptied in minutes! Well, I worried that Daphne could have been affected by low frequencies, because she'd often stay up all night, working in the studio. I later added a high‑pass filter to remove the subsonic frequencies, for safety.

"I carried on working every day at Tower Folly while she was in hospital; I had free rein to go anywhere in the house. Whether one of the house staff had seen me somewhere, and thought I was up to no good, I don't know… Because one day, shortly after she returned from hospital, I turned up for work and all the staff were lined up in front of the house, with Daphne behind them. I was told to go away and never return! I was extremely upset, as I couldn't imagine why this should happen. Daphne refused to explain. Many years later, in the early '90s, I phoned up Daphne to try and make amends. But she still refused to tell me what the problem was; she wanted me to sign a legal letter of apology, without even saying what she thought I'd done wrong! It was a great shame, but to this day, I still don't know what on earth it was about.”

For many years it looked as though Oramics would be forgotten. In November, however, it was announced that Goldsmith's College in London has bought the remains of the only Oramics machine in existence as the centrepiece of their Daphne Oram Collection, and that Graham Wrench will work with them to bring it back to life.

Update 2021.

The Daphne Oram Trust has now been established to honour her memory and work.

The Mullard House Sculpture

During the time that Graham was working at Tower Folly on the Oramics machine, Daphne was busily producing commercial music to pay the bills. One commission was for a five‑minute piece of electronic music to accompany a kinetic sculpture by Andrew Bobrowski. The sculpture was installed in Mullard House, off the Tottenham Court Road in London. Graham remembers being involved in setting up the installation in 1965: "Mullard was a huge electronics company and this was their prestigious showroom — I think it was near Goodge Street. The sculpture itself was a kind of vertical gargoyle splattered with small coloured spotlights shining outwards, and the background was illuminated with coloured fluorescent tubes. It was on a plinth that rotated, and all the lights were meant to continually change colour. Daphne had already recorded the music, so we went along to see the sculpture and to figure out how to install the sound. Their setup was very crude; the lights were controlled by two banks of 25‑way GPO uniselector switches that had come out of an old telephone exchange! They were meant to be pulse‑controlled from Daphne's tape, which was in stereo. A contract engineer had taken a terrible, cheap, domestic tape‑recorder — a BSR — and gutted it to use just the deck, modified for continuous loop play. It was connected to a replay amp that was even worse. There was nothing above 10kHz or below 150Hz coming out of it! I kicked up a fuss, and said "What are you doing? This place is where you're supposed to be showing off the latest technology, and you're using this old rubbish!” I said that Daphne was producing modern music, to the highest technical standards, and it needed playback equipment to match. I gave them the spec we required, and we left. Eventually, we got what we wanted, and the display was very successful — it was in Mullard House for quite a few years, then it was moved to Harrods.”

Daphne's soundtrack, entitled Episode Metallic, can be heard on the Paradigm Records CD Oramics.

Oramics & Industry

Graham Wrench recalls that he and Daphne Oram had several visits from officials of the Patent Office: "Daphne wanted to patent the machine, so they came down to Fairseat to see it. They had some very strange ideas! It's too advanced, they said — there's no need for it. To them, everything needed to be industrial. I remember they suggested that because the Oramics machine could produce certain frequencies of sound so accurately, it could be used in a shipyard: after all the holes had been drilled, they said, the steel plates of the hull could be vibrated at the right resonant frequency to make the swarf fall off! Daphne was not impressed.

"What they did point out, though, was that if the system was patented in Britain, it would then need to be patented separately in every other country in the world, which would cost a fortune. They said if it was only patented here, the Americans would just pinch the idea. So it was better to not patent it at all — just keep quiet about how it worked! And that's what she did in the end.”

Another visitor to Tower Folly was Tristram Cary, already well known as a pioneer of electronic music. He was later to have a hand in designing the EMS VCS3 synthesizer. "Tristram came down to see the machine,” says Graham, "and at first he was aghast! It was unlike anything he'd seen before. But after he'd taken a bit of time to figure it out, he was very impressed. He realised how quick and easy it was to use. It was, you see — playback was instant. Well, it was instant once the paint had dried…”